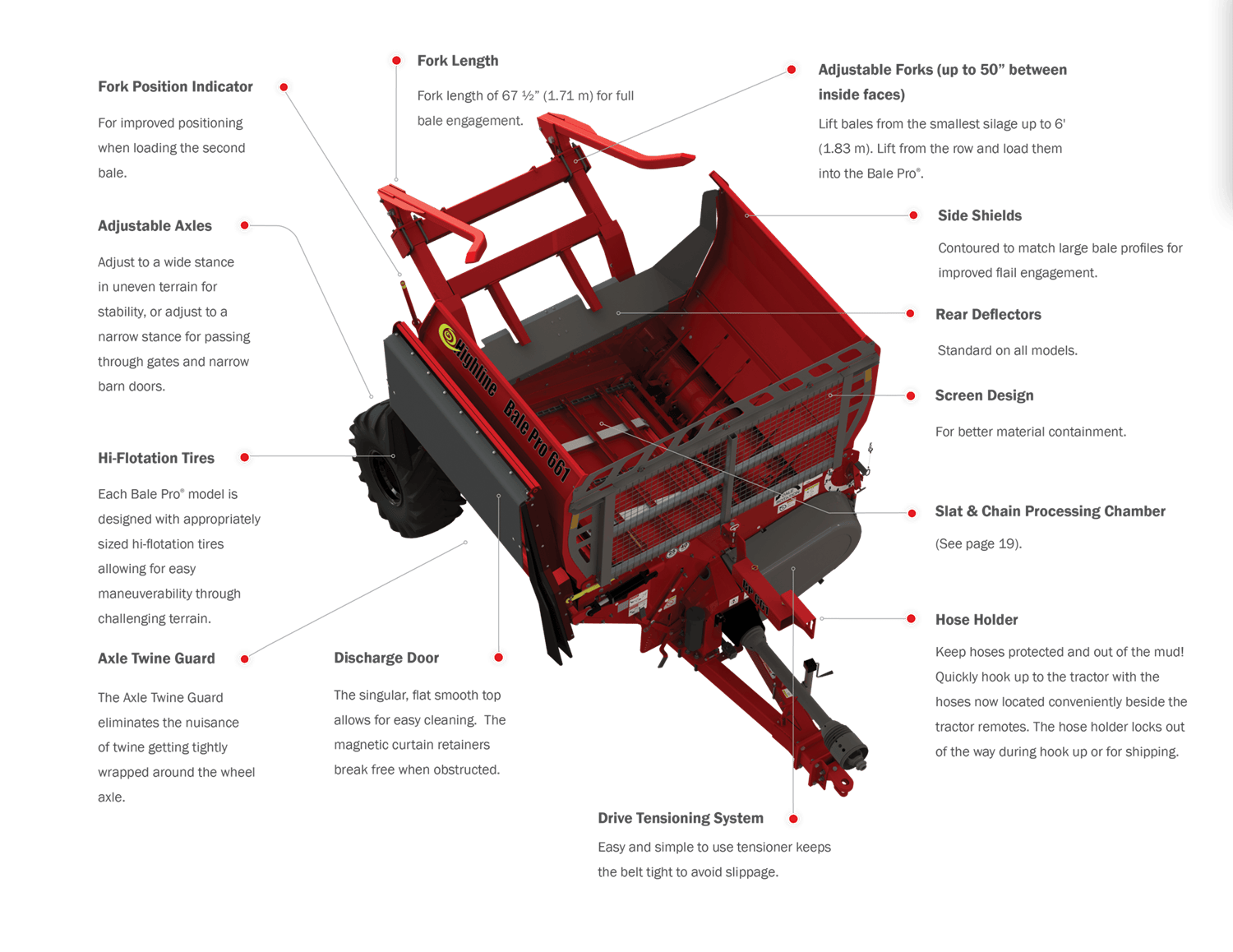

Features & Benefits

Discharge Door

The singular, flat smooth top allows for easy cleaning. The magnetic curtain retainers break free when obstructed.

Rear Deflectors

Standard on all models.

Screen Design

For better material containment.

Side Shields

Contoured to match large bale profiles for improved flail engagement.

Hose Holder

Keep hoses protected and out of the mud! Quickly hook up to the tractor with the hoses now located conveniently beside the tractor remotes. The hose holder locks out of the way during hook up or for shipping.

Drive Tensioning System

Easy and simple to use tensioning keeps the belt tight to avoid slippage

Fork Length

Fork length of 67 ½” (1.71 m) for full bale engagement.

Adjustable Forks (up to 50” between inside faces)

Lift bales from the smallest silage up to 6' (1.83 m). Lift from the row and load them into the Bale Pro®

Fork Position Indicator

For improved positioning when loading the second bale.

**Click photo to expand**